Power Battery

Depending on the lithium battery production technology for more than a decade, Veken Power Energy brings in the advanced power battery manufacturing technology in South Korea and Japan, forms the battery cell system of high energy intensity and high safety that focuses on lithium iron phosphate, lithium ion and NMC. It may produce the battery cell products such as soft packed power battery and aluminum shell power battery. It may also provide the individualized battery solution according to different demands of users.

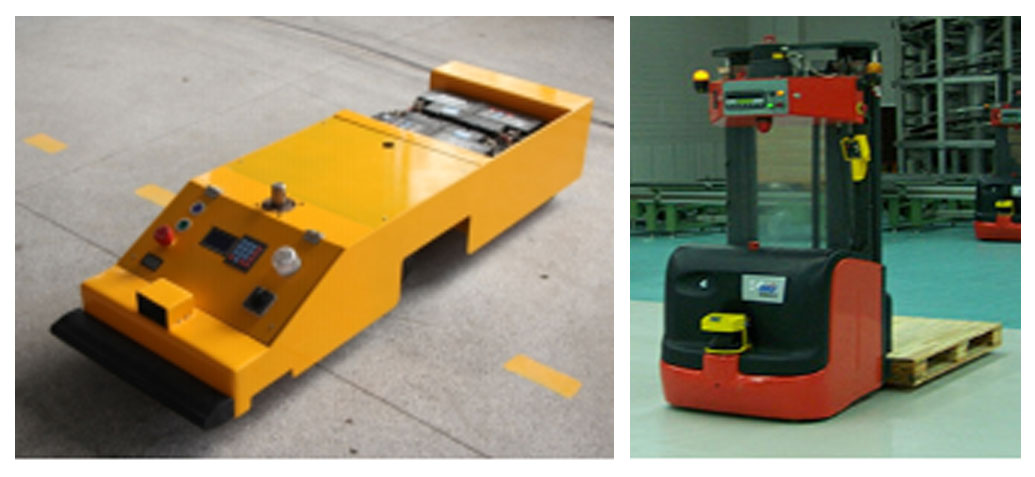

In face of the future huge application market of the power battery, Veken Technology sticks to the differentiated development strategy, focuses on the market segment, optimizes resources and input, increases investment in terms of R&D, technology and equipment, improves the product quality, actively expands the battery market in the emerging application fields such as the passenger car, low-speed car, dumper, forklift truck, AGV, electric appliance, intelligent household, vacuum cleaner, intelligent travel (electric bike, electric balance bike), small garden tool, service robot and small health care instrument, toy, energy storage.

-

High energy intensity

-

High safety

-

Individualized plan